Injection Molding Set Up

A&T Human Resources

EMPOWERING CAREERS, BUILDING FUTURES

Role Description

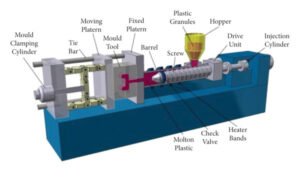

This is a full-time on-site role for an Injection Molding Set Up position in Scarborough, ON. As an Injection Molding Set Up, the role holder will be responsible for assembling and setting up injection molds on injection molding machines, performing process adjustments, verifying product quality before the start of production, and ensuring the operation runs efficiently.

Qualifications

- Diploma or degree in Mechanical Engineering or a related field

- Minimum of 5 years of experience in plastic injection molding set up

- Knowledge of injection molding machines and various types of molds

- Ability to troubleshoot various types of molding issues

- Strong understanding of process control parameters

- Ability to read and interpret blueprints

- Strong attention to detail and ability to perform repetitive tasks

- Good communication skills and ability to work well in a team environment

- Ability to lift up to 50 lbs, and stand for prolonged periods

Duties

- Perform set-up, start-up, operate and trouble shoot injection molding machines and assembly machines as per MRP production requirements

- Start-up the machines fine-tune and submit first-off for QA approval • Establish all Injection Molding processes are stable and correct

- Analyze and improve process not meeting minimum requirements of quality and productivity • In the absence of the Production Supervisor they will assume responsibility for the shift.

- Participate in Team Meetings, Corrective Actions and Team related activities • Machine set-up as per the approved set-up specification. Focus on set-up time reduction.

- Creation of the Specification Sheet by recording the set-up parameters in the computer. • Verify that all specification Sheets are current and up to date

- Verify that all workstation layouts are correct and accurate • Prepare the tool tag repair/maintenance request and enter into the MRP log.

- Update tool locations in MRP and keep it current at all times • Clean the molds daily as required by PM • Troubleshoot processes and equipment as required.

- Actively participate/initiate problem resolutions and continuous improvements of entire plant operations. • Communicate any issues or nonconformances of process or equipment to the Production Supervisor.

- Ensure that all machines and auxiliary equipment are in 100% good and safe working order. • Notify the Production Supervisor of any malfunctioning equipment or safety issues immediately.

- Have a clear understanding of machine and equipment functions and safety devices and follow safety procedures. • Participate in Initial Samplings • Initiate and/or provide training as required

- Any other duties required to maintain production and quality relating to process

- Assist in maintenance and any other duties as required by the Production Supervisor. Requirements:

- Excellent Injection molding set-up and processing knowledge

- Minimum 5 years’ experience with plastic industry preferable in the automotive industry

- Excellent communication and organizational skills

-

-

Crane experience is a strong asset

-

Job Features

| Job Category | General labor |